What We Offer

Products

CAN Engineering Worx is aware that, in the high risk environment of mining, quality is of the utmost importance to ensure the safety of all personnel.

For this primary reason we design and manufacture our products to the highest standards possible and provide additional services to further ensure a safe working environment for all.

Currently, CAN Engineering Worx holds patents for the Spillminator and Pipe Bulkhead Chutes that are being used by Anglo Platinum, Goldfields, Anglo Gold Ashanti and others.

Our footprint includes the regions of Carletonville, Rustenburg Mines, Eastern Limb, DRC, Zimbabwe, Indonesia, Northen Cape & Zambia Copperbelt which enables us to provide a quality service across the globe.

BROADENING THE HORIZON

CAN Engineering Worx, through its continuous research and development, is now also supplying the following items to the mining industry:

- Stope Grizzly’s

- Pneumatic and hydraulic tip doors

- Supporting mechanized mining

CUSTOMISED SOLUTIONS FOR OUR CLIENTS

All our clients have specific needs, unique to their operating environment. CAN believe that every turnkey solution we offer should be customized to meet these needs. For this purpose an on-site assessment and consultation is done to determine the exact needs of the client.

Our service includes measuring, designing, costing and a detailed delivery schedule.

All designs, including that of the Spillminator packages, adhere to mining industry specifications while still meeting the client’s unique requirements.

Drawings, Discrete Element Methods (DEM’s), Finite Element Analysis (FEA’s) and designs are scrutinized and signed off by a professional engineer to ensure quality and accuracy before manufacturing starts.

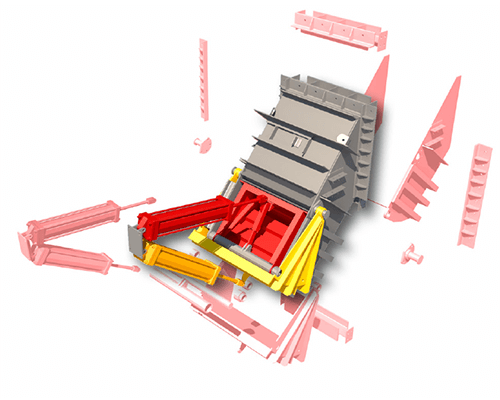

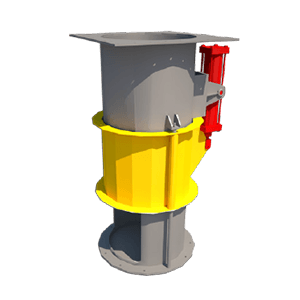

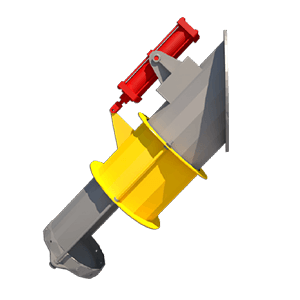

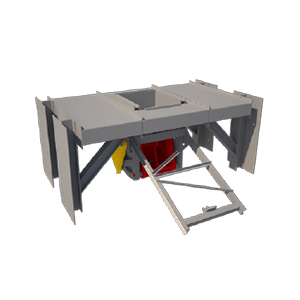

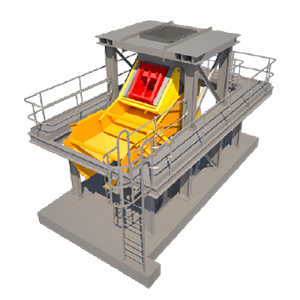

Spillminator Chute

We offer SIDE WALL CHUTES, HANGING WALL CHUTES, and BELT FEEDERS.

- In accordance with SANS specification 0208, the chute is designed for a nominal design pressure of 840kPa in platinum mines and 600 kPa in goldmines.

- 840 kPa is equivalent to a 30m ore pass filled with UG2 slurry (hydrostatic head).

- The design code states that the hydrostatic head will stay 840 k platform 30m upwards.

- The standard throat opening on our Side Wall Chutes is 11OOmm x 1OOOmm, and on the Hanging Wall Chute 1200mm x 1200mm, with an over-break of 400mm. Designs can be adapted to accommodate client requirements.

- Both the doors are designed to withstand direct pressure of 840 kPa.

- A risk assessment on the operation and maintenance procedure is available on request.

- Our standard liners are based on Hardox 450 liners. Any liners can be supplied to accommodate the client’s requirements.